|

A serious problem

with the screens:

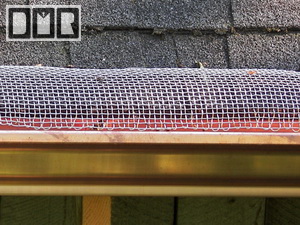

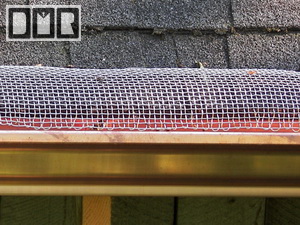

For the last decade and a half I had felt the copper screens that were available

were not strong enough, compared to what I use over the aluminum gutters

I install. But those screens are steel with just a black powder bake

finish and will start to rust within a couple decades. I had searched

for a supply of better rust free screens, but could not find any other

source designed for gutters. My hands were tied, but I now had to do

something about it. I had used these same copper screens in the Leaf-catchers

I make as well.

I now found it necessary to find an alternative source, because I recently

ran into a problem with my supplier of copper gutter screens on the

prior 2 houses. I discovered without warning the makers of these copper

screens decided to make them with a thinner copper to save costs. So

in stead getting better screens, they are now even flimsier. It seems

they did this to avoid raising prices even further, with the high cost

of copper. I cannot get them to budge on this issue, even after explaining

how all clients getting copper gutters across the Nation are expecting

better than standard. Not substandard durability.

I found a

source for stainless steel mesh screen material that I could cut to

size, which are about the same cost (without the hinge/clips

to attach them)

and tried them out on this gutter job, but they required a great deal

more processing on my end to bend over the ends of the wires so they

would not come apart like a frayed edge of fabric. I had to bend an

arch in them, which scratched up my sheet metal bender. Then to put

the clips on. I would be willing to put in the extra effort and they

are stronger, but I am still not happy with the look and functionality.

The hinge/clips are virtually useless and they are too irregular looking.

The biggest problem I have run into trying to find a better

product is the cost. Being a small time contractor I cannot buy them

in large volume to get a reasonable discount in cost. They want more

than I pay for the gutter materials. I would like to keep the cost of

screens well below the cost of the gutter it's self. My client after

this decided to just go with the black steel screens for half the cost

I was charging for the flimsy copper screens, realizing the would last

just as long.

The cat-walk boards they had made to access the large plate

glass window on the side of the living room were showing a lot of deterioration,

even though they were well under the eaves of the roof. The big 4x12

beams they were mounted to were much worse, so the client had me do

what I could to rebuild them.

|