|

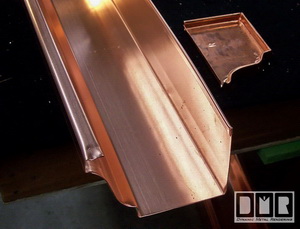

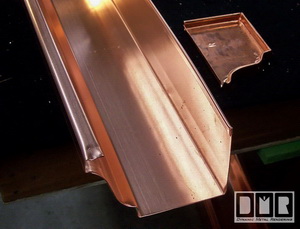

Standard Endcaps

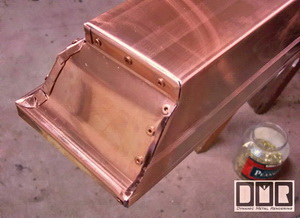

Below is an example of a standard

simple press-on endcap. It works just fine and goes on quick and

easy, so this is what pretty much all other installers will use.

I have yet to see or hear of any one else who is willing to offer the

custom mitered endcap that I do on most copper gutter jobs, shown below

in the next section. I used this standard endcap since this end

of the gutter butts up against the siding, so a mitered endcap would

have been a waste to do on this end. The cost was $9 for the

standard press-on endcap, caulk, paint, and the labor to seal and crimp

it in place.

Here

is how it is done: |

|

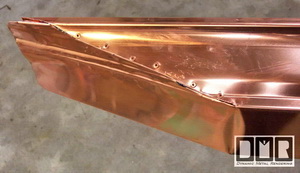

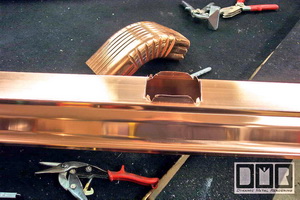

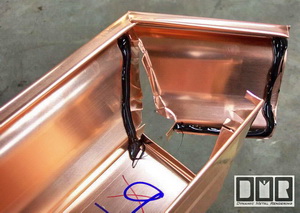

Make sure the end is cut off straight |

Press on the preformed endcap over

the end of the gutter |

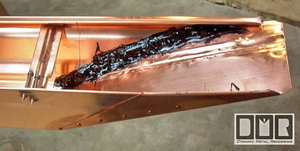

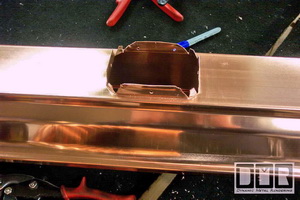

Here it is from the inside |

Run a bead of caulk into this seam

and press it in deep with a finger |

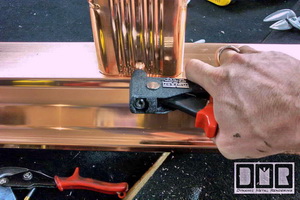

Crush the outer flanges with pliers

or a 3" seamer tool, and then make

these 6 crimps to lock it on |

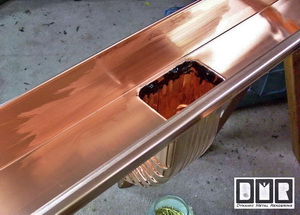

Spray some dark paint over the caulk

inside the gutter to shield it from the sun |

|

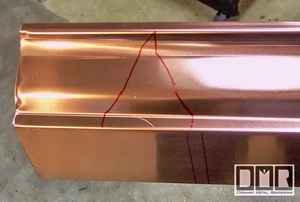

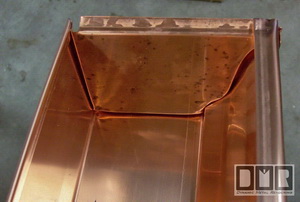

Mitered Endcaps

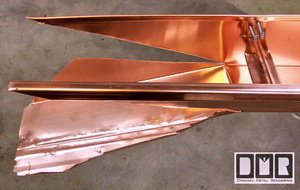

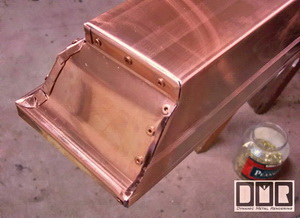

Below is an example of our custom

mitered endcaps we do on most copper gutter jobs. We do not try to

claim it works any better than a simple push-on endcap shown above, but

it sure does make the end of the gutters look a lot better. It

takes the same sort of effort and time as fabricating and sealing a

corner, so I charged the same $35 extra labor for each one. And

there is the cost of the extra 5" of gutter run-out needed to make it,

so that adds $3.75. The final cost of our custom mitered endcap is

$38.75, compared to the $9 of the standard press on endcap, so it is

really a $29.75 difference per end.

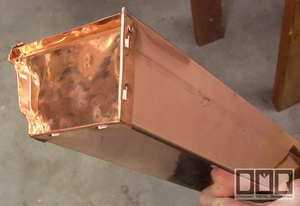

Here is how it is done: |

|

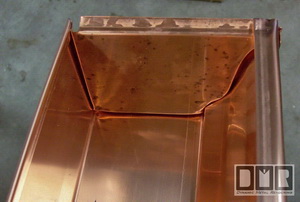

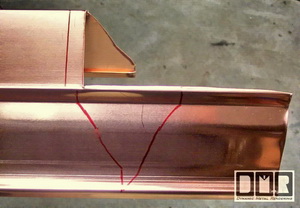

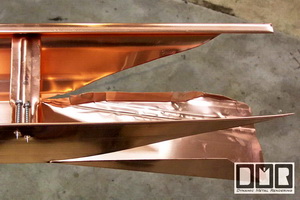

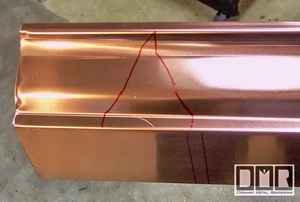

Mark the cut or bend lines on the gutter |

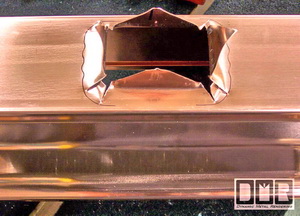

Cut the bottom and back side out |

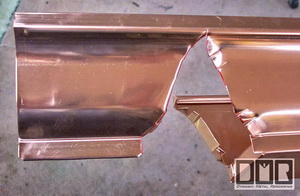

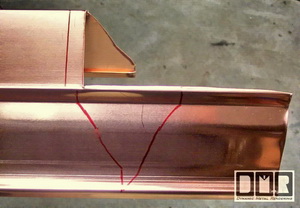

Finish the cuts and bend the tabs in |

Here it is from the other side

|

|

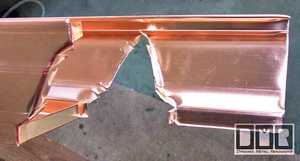

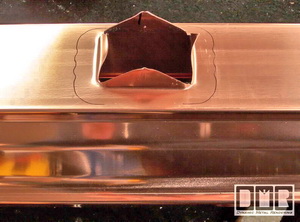

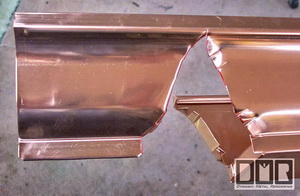

And from the top

|

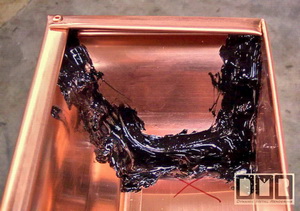

Caulk and fold this part over |

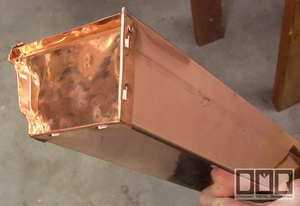

Here it is closed off but not sealed |

Here is the back side |

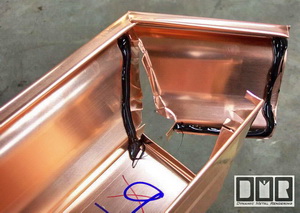

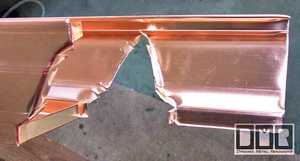

I begin riveting from the top down |

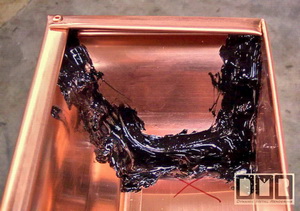

Looking inside the gutter |

These tabs need hammered over the side |

Here the tabs are bent over |

Caulk the inside over all the rivets

and seams, working in with a finger |

Smoothen the caulk out with some dark

spray pint as a solvent, working it in

again with a finger |