|

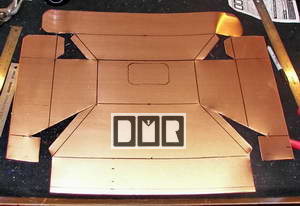

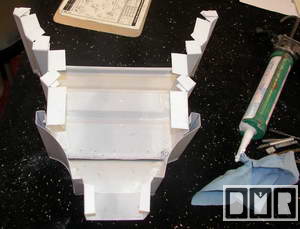

They had me replace 4 exterior custom scuppers in white aluminum and

copper for the 2 built-in scuppers seen here, so they would last

beyond the 50 year roofing. The last repairman had covered this

rusty steel with aluminum foil used for cooking as a fix to keep it

from leaking into the house walls, so of course that did not work. I

could not believe my eyes when I saw it! As you can see the rust

holes under that foil were large enough to pass my fist

through.

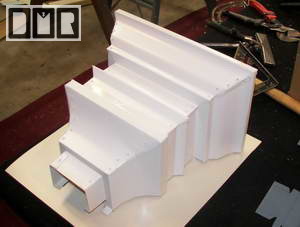

The next

photo shows the temporary repair I did with aluminum just to get

them by a few months until I could fit their job in my schedule and

fix this properly with copper. I took this shot (below) of the other

scupper that was not as bad off from inside the

house to see the staining of the wood under it.

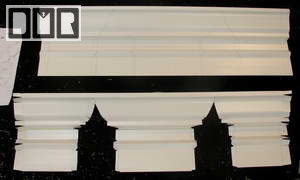

Believe it or not the previous front

gutter repair was even more ridiculous. Someone had loosely set some

10' long 'U' shaped galvanized steel troths inside the built-in

gutter in front. Besides the fact that the seams were loose and not

sealed together was bad enough, but how the rain would largely not

even go into that new troth was even more insane, being loose front and

back with no flashing to make the rain go into it. Even before they

stuffed the old gutter with this other metal the opening was so

narrow you could not get your hand in it to clean out the debris and

there was nothing to attach a screen to. In stead of doing in the

front like they did ion the back by covering up this old gutter and

just mounting the new gutter over the edge, I contracted to fit a

new copper gutter above the eaves like before, but this time it

would be a much more functional system.

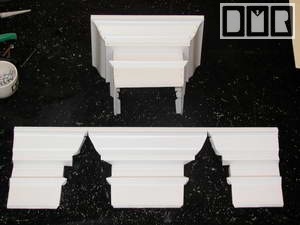

While up on a 2 story ladder I had to carefully cut the old

steel out of here in pieces with an electric shear. Then inspect the

wood for repair and replacement. I added hundreds of deck screws to

help hold it together better. Since this took several days I brought

some flat aluminum sheet metal with me to cover the exposed part as I worked

across this 40'+ span.

The back of the old steel gutter worked as the drip edge

flashing, since I was not able to remove it without tearing up the

roofing shingles. If you click on the right photo it shows the

copper flashing sealed to the outer face of the gutter to cover that

gap. |