This clearly shows the 2x2 ribs. Many of which I

scabbed off of the old trailer. This is looking from behind with all

the ribs now built. I still had some cross braces to install on the

last two ribs. I had built the rear door frame. To minimize time off work, I

set the dimensions to use the old doors again.

Here below

is the first white pre-painted aluminum skin going on. I was impatient, and did not have all the ribs

built yet, but this will help hold the frame steady. You can see

there were no ribs past the wheel well. I left the front side open

to install the side door in front of the wheel well.

Since I wanted to make this upper shell wider than the old trailer, I

had to figure out a good sturdy way to build a

floor that extends outside of the steel trailer frame out to the outside

of the wheel wells, I was glad I did, as it made the interior

much more usable in moving around the machine.

The next side wall aluminum skin goes on over the ribs and under the

fascia board that I planned to mount the gutter onto. I had not yet cut the aluminum sheet

metal skin out over the wheels to fit around the wheel well.

Then there

is the next side wall aluminum skin on, shown from the inside rear. This

shows one cross brace before I cover it with an aluminum sheet metal

covers. I still have to finish closing off the wheel well on

the inside of the trailer, so it would not make a

horrible mess inside

the trailer on

wet days.

I

assembled this trailer frame with all screws and bolts. Absolutely no

nails. This is the fascia board I am installing to mount the gutter sample

onto. I would have loved to have more of an eave over hang, but the

trailer is already 7-feet wide w/o the gutter samples. Once I have the gutters on, it will

be over 7' 8" wide. The limit for a vehicle on the roads is 8 feet

wide. My work vehicle is only 6' 4" wide, so the trailer was sticking

about 9" out on each side of the car pulling it. The rear visibility

is rather compromised as it is, and my turning clearance is an issue.

I have to be very careful to give a wide birth, so as not to hit things

that my work car was clear of. Later I decided to just remove the gutter

samples, since very few new gutter clients would have a chance to see it

before the sale. It was cute, but

kind of pointless.

Here

is another picture that Tia took from an overhead view of me working on it. This was before I installed the many wood screws

with steel and rubber washers into the new white aluminum skins. Again,

I needed to pre-drilled the holes for those screws

to avoid any splitting or cracking of the small 2x2 boards. It was tricky

to line up the holes I drilled to be centered in the board

hidden behind the aluminum sheet metal.

The over head

clearance of the garage door frame was very close to the roof of the

trailer by just an inch without the roof panels on the trailer

shell. As soon as the weather cleared, I was able to move it

out of the work shop to install the roof panels. It would have been

easier to make a simple flat roof. Beside the cute dramatic look of a small

house, I hate the idea of rain water and subsequently mud puddeling on the roof panels.

It

also makes the removable roof panel much more stable on the freeway to have this

A-frame

roof. The removable panel is to be able to have a 400lb coil of new

sheet metal lowered onto the gutter machine spindle with a fork lift.

This

shows the back doors, that were off of the old trailer.

I was running out of

time and needed to put off building the new door that now swings up on a

pair of hydraulic supports. The size of the frame needed was just fine for the new

door, so luckily it was not a conflict.

This

is the side view, outside of the work shop. The roof panels are now ready to

go on.

It made me nervous to be off work for so

long with bills pilling up, so I was

in a little of a panic to get this ready to get back to my gutter work

jobs I had on my schedule.

Here

it is looking down into the trailer from the front. You can see that

all the ribs are built and braced. I also decided to spray paint the

wood to make it look more even.

You can also see the white sheet metal I

used to closed off

the inside of the wheel wells, to keep the splash of the rain water from

being flung into the trailer while being pulled on rainy days.

This

is another view from on top, looking forward.

The opening just above the coil is where I will be making

the removable panel to lower the gutter coils down into the gutter machine

spindle. The

coils need to loaded with a fork lift since a full coil is about 400

pounds. This gutter coil of pre-painted

aluminum sheet metal is 11 7/8" wide. This coil is only about 2/3

of a full coil, or else it

would be larger than the spool side walls.

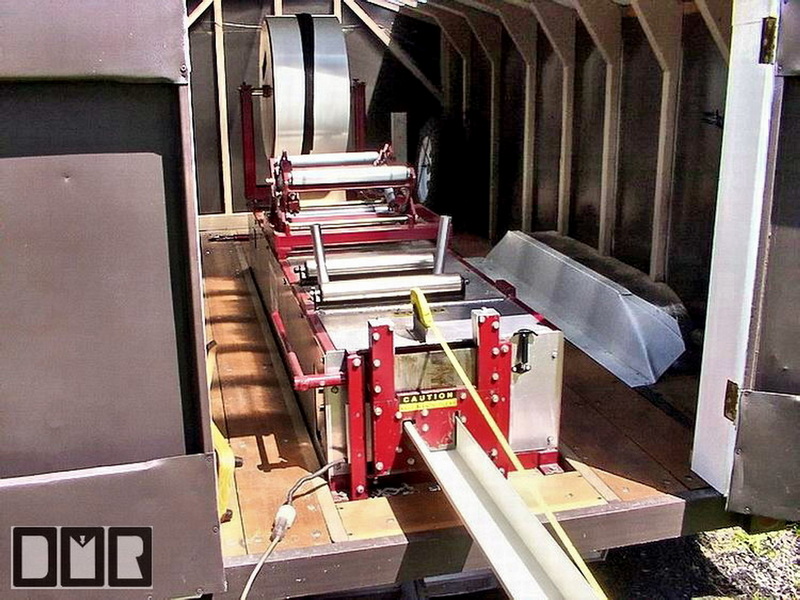

This

shows the spool in the back of this picture, and the cradle in the

middle of the machine, and the cheap cradle I installed in the fore

front. Then I have the pocket for my 100' tape measure in yellow.

Again, the inside of the wheel wells are

closed off.

Another

view of the interior showing the side door on the left side, and the wheel

well aluminum inside cover, but still no roof panels yet. The

aluminum sheet metal I use come in sheets that are 4' X 10'. They are

painted white on one side and musket brown on the other side.

I chose to make this trailer with the white sides, with a brown

roof. So that means the ceiling is white.

Here

is the first roof panel to go on, leaving a space in the middle for the

skylight panels. The panels have a lot to do with the structural integrity

of the trailer shell.

I found this system to worked quite

well, using 2X2 boards and the

aluminum sheet metal screwed on with 1.5" screws that have steel and

rubber washers. Those screws are spaced about 6" apart. I made a

smaller trailer with an aluminum frame and covered with aluminum panels

and riveted them on with large 3/16" rivets, but the vibration of the

trailer in transpo would work those rivets loose

Here

is a shot of me screwing down the left roof panel, with Tia taking this

photo.

The back doors are open wide as you can see. If the sheet

metal was white on white instead, that would have been best

for function, so the light would reflect off the walls, making it

lighter inside. I could have made it all brown on the out

side, but I wanted a white look on the outside. I only made the roof

brown to look more like a house roof.