|

This

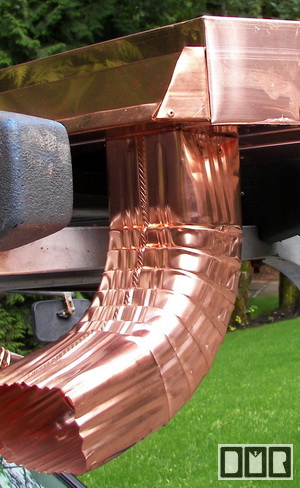

is the back side of his house at 827 NW 25th Ave. I have done

this sort of work on several houses, but this was one I managed to

get some good clear photos of with our 4 mega pixel digital Kodak

camera.

This

is a large 2 story house and was also originally built without gutters, but

again, they had a gutter contractor install some crappy gutters

later on.

The gutters I took down were the same type as I

install, but they were hung with straps that wrapped around the

gutter, and then the strap extended from the center of the top of

this gutter, over the roof, and was nailed on top the roof.

That means the gutter was hanging in mid air,

and would sway in the wind. the roof had to over lap the

gutter half way, making it impossible to screen, very hard to clean,

and in a heavy downpour it would actually shoot right over the

gutter all together.

When I took the old gutters down, I not only

needed to get the gutter measurements, but I had to carefully

visualize and calculate the angles and measurements for the size of

the boards and the custom sheet metal fabrication needed here.

This house has most of it's gutters over 2

stories high. It was a very steep roof of a 12/12 pitch. That

is a 45 degree angle, and cannot be walked on. The soffit was

also at this 45 degree pitch. This was the best thing I could come

up with to resolve this problem so I had a vertical fascia board to

attach the gutter to, and have it look like it was made to fit the

style of the house.

They place this wood

molding up just under the edge of the roof, but this one was

especially difficult, since the molding was horizontal, instead of

at a 45 degree angle. There was nothing to screw the fascia

board onto at all. Some of the wood molding was cracked,

broken, rotten, and in some places missing all together.

I had to first screw this un-painted board you

see in the middle, straight up into the wood molding, so that I had

something to screw the fascia board onto. Where the wood was

rotten, I had to use extra long screws that would reach through to

the plywood roof, without having the screws puncture the shingles

above.

After I fastened the primered fascia board to

that bare wood, I installed this custom aluminum sheet metal to act

as soffit, and also cover the bottom of the fascia board. It

also serves the purpose to hold out and support the bottom of the

fascia board. I chose a green pre-painted aluminum to make

this with. It is the same type of metal the gutters are made from.

but I used a wider 15"x 120" sheets to make this from.

I used special ribbed finish nails to fasten

the sheet metal in place up underneath, and there on the fascia

board. It was very sturdy when I was finished.

As

shown above, this shows the gutter on the new fascia board.

the client, Mr. Smith was very pleased with my work, and even

complimented me, saying how it looked better than he had imagined.

It is satisfying to see an unusually

complicated job, that no one else wanted to tackle, go so

well. And it is also great to get those kind of comments.

|