| Here

is the roof panel from on top, before I installed the skylight panels and

the removable panel.

|

|

|

|

DMR. |

Here

I have the rear skylight paner on and locked down. I have the front

skylight panel on, but the front triangle piece is a part that goes on

over it and then is screwed on to hold the skylight panel down in the

front. Here

I have the rear skylight paner on and locked down. I have the front

skylight panel on, but the front triangle piece is a part that goes on

over it and then is screwed on to hold the skylight panel down in the

front.

|

|

DMR |

| This

is the interior without the removable panel on. |

|

|

|

DMR

|

Here

is the top view without the removable panel in place. Here

is the top view without the removable panel in place.

I would have loved to have made the

trailer much taller, but with the extra weight, wind drag, and most

importantly; I could not reach the screws for the removable panel, I was

not able to make it any higher. As it is, it is all I can do to reach the

screws with the drill/driver.

|

|

DMR |

| This is

looking up from the inside through the skylight. A much nicer

addition from the old trailer I made. This material is made out of a

two layer polycarbonate plastic formula, that will not yellow and

fog like acrylic plastic. It is also very impact resistant too. |

|

|

|

DMR |

Here

of course is the finished trailer, sans the new rear door. As you can see,

I made a sample gutter, which also displays the no-clog gutter options and

leaf-catcher. The gutters are in a color called 'wood beige' and the

downspouts are painted 'musket brown', just like the roof and the inside

of the wall panels. Here

of course is the finished trailer, sans the new rear door. As you can see,

I made a sample gutter, which also displays the no-clog gutter options and

leaf-catcher. The gutters are in a color called 'wood beige' and the

downspouts are painted 'musket brown', just like the roof and the inside

of the wall panels.

|

|

DMR |

| This is the

top view of the trailer, clearly showing the skylight panels and the

removable panel in place. Four screws hold it in place, two on each

side. For the sake of high wind and rain, the removable panel is

tucked under the front skylight panel, and over the rear skylight

panel, since all the high speed travel will be in the forward

motion. |

|

|

|

DMR |

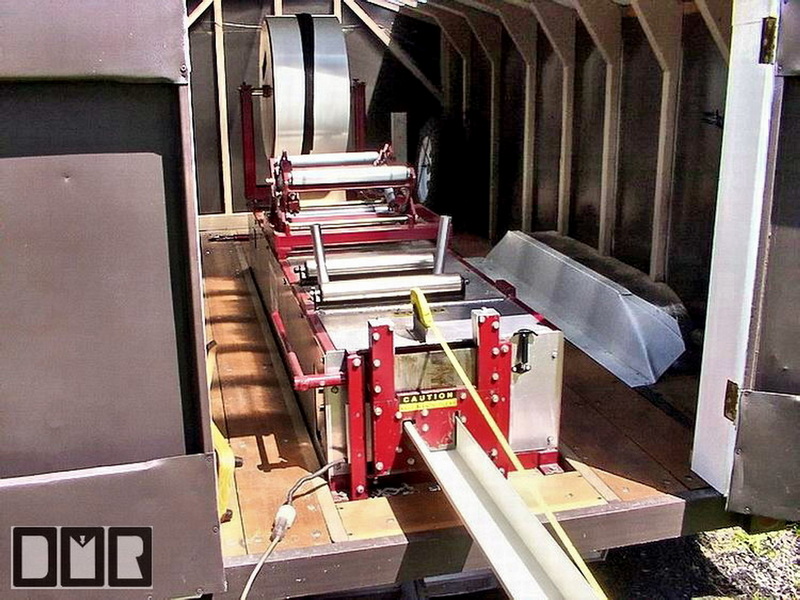

Here

is a picture of some aluminum sheet metal being run through our

roll-forming machine, and resting on a portable roller stand.

As I have said before, It is important to me that I keep my machine out of

the elements, as they do not make a machine that has all non-corrosive

metal parts. Most, if not all the bearings are simply made out of

steel. I have replace many of the bearings in our machine recently, even

though it has never been rained on. It is a crime that most of the

other installer still have their machine exposed to the elements, due to

the simplicity. They especially do this for the loading new sheet

metal coils onto the spools. Their rusty machines will scratch up

the paint, if not dent the sheet metal of the new gutters. A fact

that you will not get from these contractors until it is too late. Here

is a picture of some aluminum sheet metal being run through our

roll-forming machine, and resting on a portable roller stand.

As I have said before, It is important to me that I keep my machine out of

the elements, as they do not make a machine that has all non-corrosive

metal parts. Most, if not all the bearings are simply made out of

steel. I have replace many of the bearings in our machine recently, even

though it has never been rained on. It is a crime that most of the

other installer still have their machine exposed to the elements, due to

the simplicity. They especially do this for the loading new sheet

metal coils onto the spools. Their rusty machines will scratch up

the paint, if not dent the sheet metal of the new gutters. A fact

that you will not get from these contractors until it is too late. |

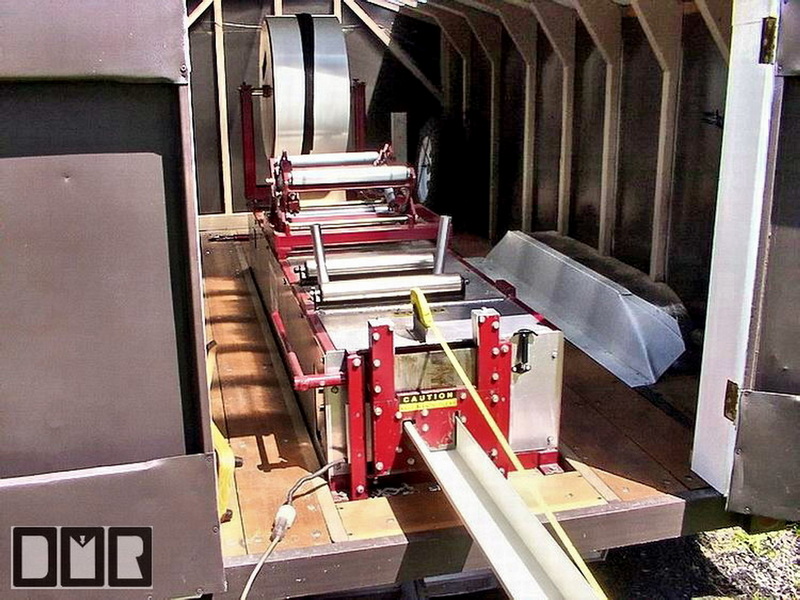

| Here is a close-up

shot of the gutter being extruded from the 8 ' sheet metal

roll-forming machine we call our gutter machine. |

|

|